To begin analyzing S30V vs S35VN for hunting knife and chef’s knife applications, both S35VN and S30V steels are modern, high-performance steels developed by Crucible Steel utilizing their Crucible Particle Metallurgy (CPM) process. S30V was introduced in 2001 and S35VN in 2009, and both are currently in production by Crucible Industries LLC. S35VN can be considered a refinement of S30V, the difference in composition between the two steel alloys leads to subtle application variances which are utilized by Apex Steel Works in the production of their high quality S35VN kitchen knives and S30V hunting knives.

A comparison between the two should begin with their final application – both are extremely capable knife steels. They are practically stainless, relatively easy to sharpen, have excellent edge retention and are very tough for their class of steel. The primary difference between the two steels is the addition of niobium to S35VN which affects its carbide content.

S35VN chef’s knives will exhibit somewhat greater edge durability due to the addition of niobium carbides distributed in a finer matrix throughout the steel. This increased toughness prevents chipping and damage in a demanding kitchen environment where contact with other cutlery, the nature of food preparation against resilient cutting surfaces, and accidental misuse is an eventuality. The trade off here for S35VN is that reduced vanadium carbides due to the niobium content it has a small reduction in edge retention. However, this is paired with a perceived increase in ease of sharpening, which is desirable in a culinary environment where an S35VN chef’s knife will see many hours of continual service.

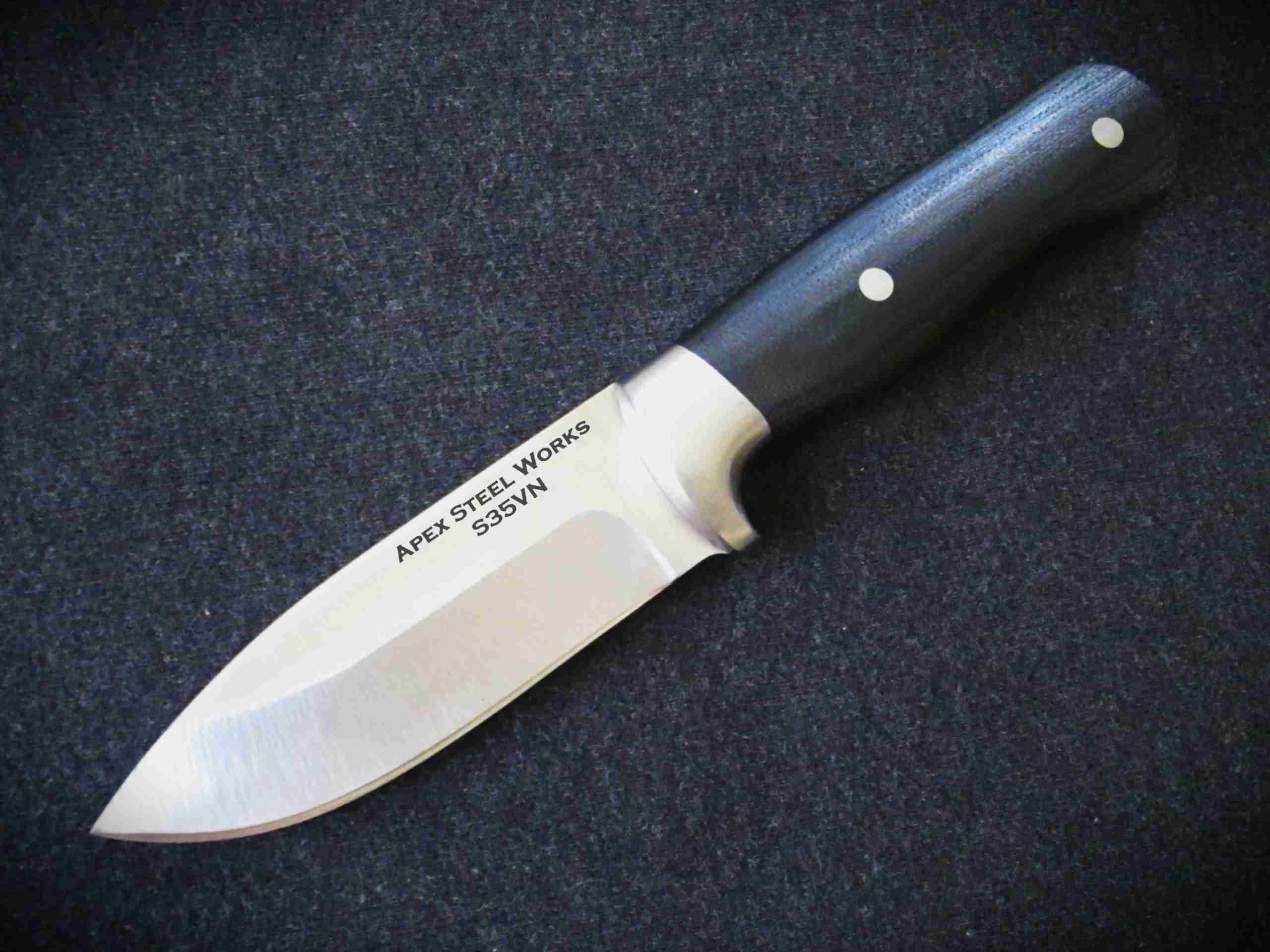

In contrast, our S30V hunting knives are designed with a different blade geometry with little edge flexion planned for its usage – the toughness of the steel is less of an issue than a kitchen knife which will routinely encounter bones in a vigorous manner, frozen materials, and tough cutting boards. The somewhat more difficult sharpening process is also less of an issue – paramount to success in the field is lack of interruptions and the edge holding of an S30V hunting knife is a definite benefit in that case. The larger vanadium carbides exposed in the matrix at the cutting edge “last longer” and are “harder” while requiring somewhat more time to maintain via sharpening or stropping when service is required. S30V has an ultimately sharper potential edge which is worth the trade off of some durability in a hunting knife application.

Heat treatment and machining of S30V and S35VN

S30V and S35VN, as stainless tool steels, require a neutral atmosphere or shielding from oxygen of some manner due to the high temperatures and long soak times required for austenitic conversion to martensite during the quench. Both steels are brought to 1900-2000 degrees Fahrenheit and held for fifteen minutes, the hold time resultant from the typical thickness of knife blades, and then quenched in a positive-pressure manner down to room temperature. A cryogenic treatment is immediately provided, then a double temper at ranges from 400 to 600 degrees as soon as the cryogenic cycle is completed. Depending on blade geometry and intended use the parameters for S30V and S35VN may vary, but are optimized and tested to provide reliable results and a fine quality product. Both S35VN and S30V, as hunting knives or chef’s knives, will finish at 59 to 61 Rockwell C hardness utilizing Crucible’s recommended processes. They both are similar in resistance to machining operations in their annealed state with S35VN having a slight lead in its ability to be ground. It and S30V both are easier to machine than S90V or several other tool steels in their class, but are more difficult than lower alloy steels such as 420. The choice of S30V vs S35VN is almost entirely determined by usage and blade geometry due to similar heat treatment schedules and machining procedures.

Benefits and applications of S30V and S35VN as knife steels

S30V and subsequent steels are also notable for their development primarily for the high quality custom knife market. Many members of the industry contributed feedback and testing results leading to the products available today. Modifications of S30V led to S35VN in 2009, and even more recently a more varied alloy S45VN was made available in 2019 which is the latest iteration of continual improvement upon the original specifications. These steels are processed to size by Niagra Specialty Metals in New York and further distributed by multiple secondary companies serving the custom knife community as well as directly to larger corporations producing higher volumes of knives featuring them.

The differences between high quality stainless tool steels engineered for the knife industry and cheaper grades primarily utilized for cost savings and to make a “good enough” mass market product are great. A short takeaway from the data is that the edge holding of S30V and S35VN can be as much as five times as great as that of cheaper steels. An S35VN chef’s knife versus a mass-market AEB-L competitor will lead in the kitchen by a wide margin due to far less frequent servicing of the edge to keep it cutting effectively.

Composition of S30V and S35VN steels

To detail these differences in an objective manner based on the composition of S30V and S35VN steels refer to the following list –

S30V (2001) – Carbon 1.45%, Chromium 14.00%, Vanadium 4.00%, Molybdenum 2.00%, Nitrogen 0.2%, Iron 78.35%

S35VN (2009) – Carbon 1.40%, Chromium 14.00%, Vanadium 3.00%, Molybdenum 2.00%, Niobium 0.50%, Iron 79.1%

As mentioned above, the addition of niobium to S35VN and its lower ratio of vanadium to the total composition versus S30V is the primary driver of the difference in its carbide composition and distribution. Vanadium carbides are larger and harder than ones consisting of niobium. The seemingly small reduction of vanadium by 25% and replacement of it with 0.50% niobium is sufficient for the variance in the application of the finished steel weighed against one another. The removal of additional nitrogen from S35VN compared to its predecessor S30V also contributes to the variance – powder metallurgy steel production requires a neutral atmosphere so all products of that process will contain a few hundredths of a percent of nitrogen as a matter of course.

The metallurgical properties of S30V and S35VN steel are further enhanced with Crucible’s particle metallurgy process. The steel rather than being formed into relatively consistent large ingots which then are further processed for grain refinement is sprayed via a patented process into a consolidation vessel while in a molten state. This results in small, highly homogenized particles of the desired alloy being highly mixed and a more uniform batch of steel being produced. There is no separation of alloying elements due to the atomization of the steel into particles, and no variance of initial carbide formation in the resultant product, leading to a higher quality product overall. This steel particulate is processed in a hot isostatic press operation in a controlled environment ensuring a completely homogenous, fine-grained product with controlled and consistent carbide formation. S30V and S35VN (as well as other Crucible Particle Metallurgy steels) rate very highly in performance versus steels utilizing older methods of production due to this combination of composition and production factors.

The following chart shows comparative edge holding for a variety of steel grades at a given hardness – the higher hardenability of Crucible’s products is a great contributor to its lead in performance. 440C is normalized at 100 on the scale to illustrate its acceptable performance as a knife steel, with S30V and S35VN being far newer products utilizing modern production methods such as Crucible’s particle metallurgy process.

| Steel Alloy | Rockwell C Hardness | Edge Holding |

| S30V | 61 | 150 |

| S35VN | 61 | 130 |

| 440C | 59 | 100 |

| AEB-L | 60 | 60 |

| 425M | 57 | 55 |

| 420HC | 56 | 40 |

| 420 | 54-56 | 35 |

Overall the edge holding comparison for S30V vs S35VN is within 15% of of one another, but they together superior choices. Also, there are caveats and details to this chart – the higher alloy steels with greater carbon content such as S30V and S35VN can be hardened to a higher degree than their lower alloy cheaper counterparts. This leads the cheaper steels to be easier to fabricate and keeps the cost of the resultant product lower and more accessible to the consumer. An S30V hunting knife is going to cost more to produce in wear on tooling, abrasive consumption, and raw material costs compared to a design featuring 420 grade stainless. An S35VN chef’s knife will be more durable, require less re-sharpening, and have a service life longer than any cheaper alloy. However with proper, optimized heat treatment some of these figures can be improved by higher end manufacturers with an interest in bringing good value with limited ultimate potential in the steel itself – they won’t reach the values of toughness and hardness Crucible Steel’s products do, but they can be acceptable. Another difference is that the low alloy steels are also relatively more stain resistant – with chromium predominantly featured as the main alloying agent and no reduction in corrosion resistance due to higher carbide content they are more “stainless” in nature. Elements such as vanadium found in both S30V and S35VN and the niobium in S35VN as well as later S45VN are relatively exotic but can affect the properties of the alloy in potentially negative ways – a minor reduction in stain resistance is more than a fair trade for the better edge retention.

Conclusion

With these objective performance differences in mind, S30V and S35VN are an obvious choice for high quality hunting and chef’s knives. The cost difference per knife is not insignificant as some of the cheaper alloys can cost less than a dollar per blade when produced in bulk, but the trade off is poor performance and short life when used routinely. The following information shows public, industry specific data normalized from multiple sources as well as Apex Steel Works’ experience using dozens of knife steels for decades and comparing the results – there is no reason to promote one steel or another other than to provide the consumer the best choice available and therefore strengthen our company’s reputation for producing high quality knives.

Our default recommendations for stainless knife steels are S35VN for chef’s knives and S30V for hunting knives. The amount of engineering and development Crucible Steel has put into their S30V and S35VN steels has allowed many companies to have great success producing high quality knives for decades. Apex Steel Works utilizes both of these steels as well as others when applicable to the needs of the consumer that have been learned over 25 years of industry experience making knives.